Sign in to view hidden information.

Company Introduction

Company Introduction

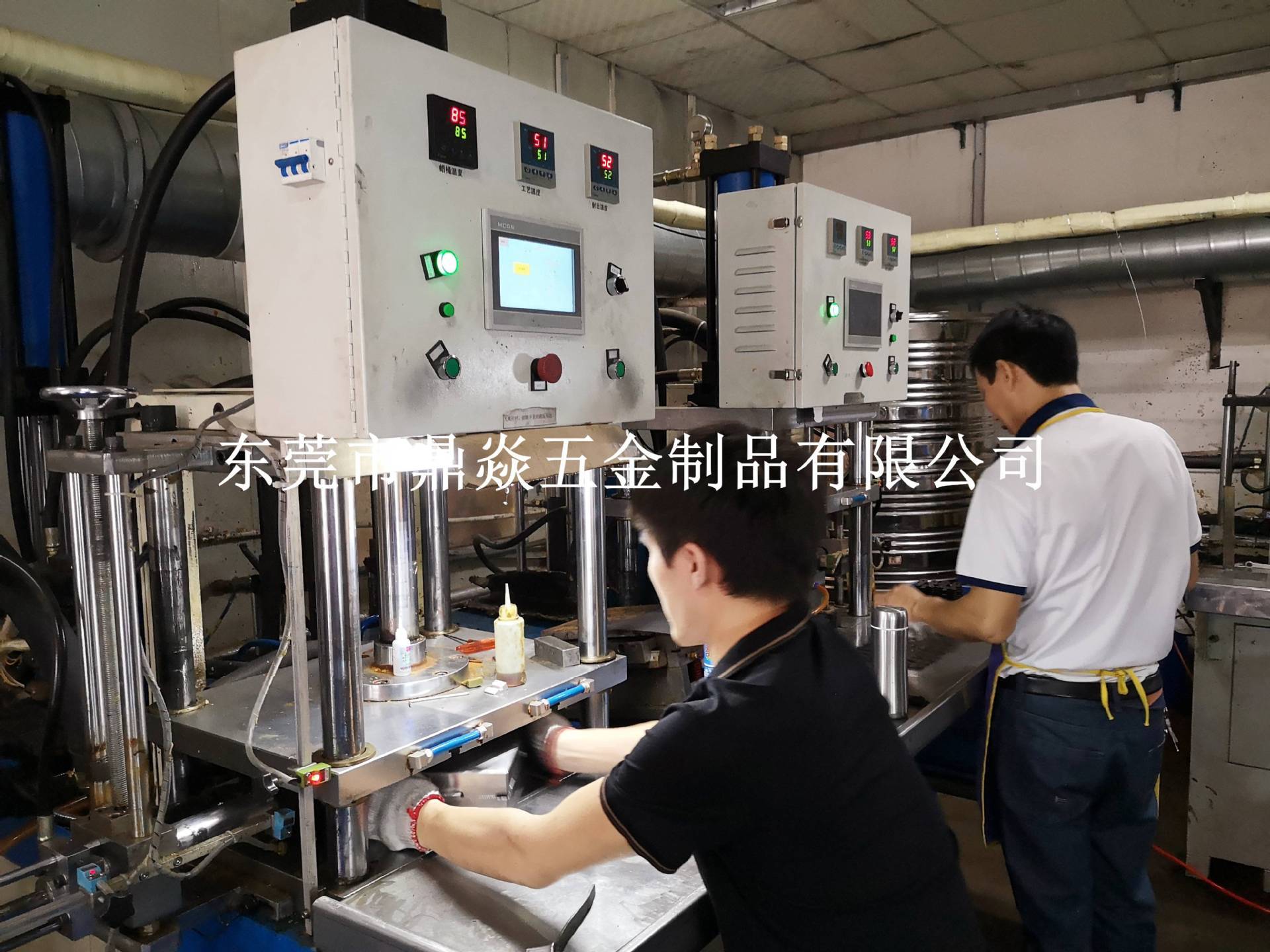

Ding Yan Hardware engaged in metal casting for nearly ten years, focusing on investment casting (also known as lost wax casting) mainly produces stainless steel casting parts, carbon steel casting parts, alloy steel casting parts, brass casting parts, and other types of hardware products, with a complete and scientific quality management system. In order to improve production efficiency and ensure product quality, Dingyan adheres to the production principle of "people-oriented, optimized equipment" and constantly introduces new equipment. Currently, there are 8 automatic cylinder free wax shooting machines, 1 automatic electric dewaxing reactor, 1 automatic wax supply system, 2 electric shell film roaster, 1 medium frequency melting furnace, 2 G20 gas pick shell shaking machines, 1 hook shot blasting machine, 2 track shot blasting machines, 4 cutting machines, 2 sand blasting machines and 1 hydraulic automatic shaping machine. Through the cooperation of multiple machines, the casting surface is smooth and smooth, without missing materials, sand holes and other bad.

Basic information

Basic information

- AddressRoom 101, Building 5, No. 10 Longyuan Street, Chang 'an Town, Dongguan, Guangdong

- Introduce

Ding Yan Hardware engaged in metal casting for nearly ten years, focusing on investment casting (also known as lost wax casting) mainly produces stainless steel casting parts, carbon steel casting parts, alloy steel casting parts, brass casting parts, and other types of hardware products, with a complete and scientific quality management system. In order to improve production efficiency and ensure product quality, Dingyan adheres to the production principle of "people-oriented, optimized equipment" and constantly introduces new equipment. Currently, there are 8 automatic cylinder free wax shooting machines, 1 automatic electric dewaxing reactor, 1 automatic wax supply system, 2 electric shell film roaster, 1 medium frequency melting furnace, 2 G20 gas pick shell shaking machines, 1 hook shot blasting machine, 2 track shot blasting machines, 4 cutting machines, 2 sand blasting machines and 1 hydraulic automatic shaping machine. Through the cooperation of multiple machines, the casting surface is smooth and smooth, without missing materials, sand holes and other bad.

patent

patent

Company history

Company history

- 2019-10 Ding Yan Hardware has been engaged in hardware casting for nearly ten years, focusing on investment casting (also known as lost wax casting), mainly producing stainless steel casting parts, carbon steel casting parts, alloy steel casting parts, brass casting parts, and other kinds of hardware products, with a complete and scientific quality management system. In order to improve production efficiency and ensure product quality, Ding Yan adhered to the production principle of

Company Introduction

Company Introduction Basic information

Basic information patent

patent  Company history

Company history